What is Micromeritics ? Importance of Study of Micromeritics

Table of Contents

What is Micromeritics?

The Science and Technology of

small particles is known as Micromeritics.

Micromeritics deals with-

• Particle

size and Size Distribution

• Methods of Determining particles size

• Particle shape and surface area

• Pore size

Importance of Study of Micromeritics

Knowledge and control of the

size and the size range of particle is of profound importance in pharmacy.

Size and surface area can be

related to the physical, chemical and pharmacological properties of a drug.

1.Particle size affect its

release from dosage forms that are administered orally, parenterally, rectally and topically

2. Physical stability and

pharmacologic response of suspensions, emulsion and tablets depends on particle

size.

3. It is also important in flow

properties and proper mixing of granules and. powders in tableting.

4. Both Tablets and capsules are

produced using equipment which controls the mass of drug and other particles by

volumetric filling. Therefore any interference with the uniformity of fill

volumes may alter the mass of drug incorporated into the tablet or capsules.

Thus reduce the uniformity of the medicine.

5. Powders with different

particle sizes have different flow and packing properties which alter the

volumes of powder during each encapsulation or tablet compression.

6.The

rate of solution depends on the several factors. One factor is the particle

size. Thus particles having small dimensions will tend to increase the rate of

solution.

For

example:

a). Griseofulvin has a low solubility by oral

administration but is rapidly distributed following absorption. The solubility

of Griseofulvin can be greatly increased by

particle size reduction.

b).

Reduction of particles size also increase the rate of absorption of

tetracycline, Aspirin and Sulphonamides.

c).

Reduction of particle size of nitrofurantoin increased the rate of

absorption. Therefore the toxic effect due to rapid absorption.

Different means of

expressing particle size.

There are

different means of expressing particle size:

Millimeter (mm)……. 10-3 meter

Micro

meter (µ m) ……. 10-6 meter

nano meter (nm)…….. 10-9 meter

pico meter ……………10-12 meter

fanto

meter………………... 10-15 meter

Particle

Dimension in Pharmaceutical Disperse system

Particle

size

Micrometer (µ m) Millimeter (mm) Disperse systems

0.5-10 0.0005 - 0.010 Suspension,

fine emulsion

10-50 0.010- 0.050 Coarse

emulsion, flocculated suspension

50- 100 0.50- 0.100 Lower

range of sieve range, fine powder range

150-1000 0.150-1.000 Coarse

powder range

1000- 3360 1.000- 3.360 Average

granule size

Methods of determining

particle size

- Optical

Microscopy

- Sieving

Methods

- Sedimentation

Methods

Particle

volume measurement:

- Coulter Counter

Method (Electrical stream sensing method)

- Laser light

scattering methods.

Methods of determining surface

area:

- Adsorption method

- Air permeability method

Sieving Method

Sieving method

is an ordinary and simple method. It is widely used as a method for the

particle size analysis.

Range of analysis:

The

International Standards organization (ISO) sets a lowest sieve diameter of 45 µm and sincepowders are usually defined as having a maximum diameter of 1000 µm, this could

be considered to be the upper limit.

In practice

sieves can be obtained for size analysis over a range from 5 to 125 000 µm.

|

| Particle diameter

Sample

preparation and analysis condition

|

1. Sieve analysis is usually

carried out using dry powders.

2. Although, for powders in

liquid suspension or which agglomerate during dry sieving, a process of wet

sieving can be used.

Principle of Measurement:

Sieve analysis utilizes a woven, punched or electroformed mesh often in

brass, bronze or stainless steel with known aperture (hole) diameters which

form a physical barrier to particles.

Most sieve analyses utilize a series, stack (

Load /Mountain or nest (layer) of sieves which have the smallest mesh above a

collector tray followed by meshes which get progressively coarser towards the

top of the series.

A sieve stack usually comprises 6-8 sieves with a

progression based on a √2 or 2√2 change in diameter between adjacent aperture.

Powder

is loaded on to the coarsest sieve of the assembled stack and the nest is

subjected to mechanical vibration for, say 20 minutes

After

this time , the particles are considered to be retained

on the

sieve mesh with an aperture corresponding to the minimum or sieve diameter.

A

sieving time of 20 minutes is arbitrary and BS 1796 recommends sieving to be

continued until less than 0.2% material passes a given sieve aperture in any 5

minutes interval

Advantages : 1. This method is very simple.

2. Not expensive

3. Easy to operate

Disadvantages: 1. Not

too much precise method.

2. Not

applicable for all disperse systems.

Sedimentation Methods

Sedimentation Method is also an ordinary and

simple method.

It is widely

used as a method for the particle size analysis.

Range of analysis:

Sample preparation and analysis conditions

In this method particle size can be

determined by examining the powder as it sediments out.

(a). In cases where the powder

is not uniformly dispersed in a fluid it can be introduced as a thin layer on

the surface of the liquid.

(b). If the powder is lyophobic, e.g. hydrophobic in water ,

it may be necessary to add dispersing

agent to aid wetting of the powder.

(c). In case where the powder

is soluble in water it will be necessary

to use non- aqueous liquids or carry out the analysis in a gas.

Principle of Measurement

Particle

size analysis by sedimentation method can be divided into two main categories according to the method

of measurement used.

1. One of the type is based on

measurement of particle in a retention zone.

2. Another type uses a

non-retention measurement zone.

An example of a non-retention zone

measurement is known as the pipette method.

In this method , known

volumes of suspension are drawn off and the

concentration differences are measured with respect to time.

One of the most popular of the pipette methods

was that developed by Andreasen and Lundberg and commonly called the Andreasen pipette.

The Andreasen fixed-position pipette consists of a 200 mm

graduate cylinder which can hold about 500 ml of suspension fluid.

A pipette is located centrally

in the cylinder and is held in position by a ground glass stopper so that its tip coincides with

the zero level.

A three way tap allows fluid

to be drawn into a 10 ml reservoir which can then be emptied into a beaker or

centrifuge tube.

The amount of powder can be

determined by weight following drying or centrifuging.

The

weight of each sample residue is

therefore called the weight of undersize and the sum

of the successive weight is known as the

cumulative weight of

undersize. It can be

expressed directly in weight units or percent of the total weight of the final

sediment..

The data of cumulative weight of undersize

is used for the determination of particle weight distribution, number

distribution,

The largest particle diameter in each sample is then

calculated from Strokes’

Law.

The

particle size may be obtained by gravity sedimentation as expressed in Strokes’

law.

Where ,

v = rate of settling

h = Distance of the fall in time , t

dst = the mean diameter of the particles

based on the velocity of sedimentation

ρs= density of

the particles

ρo = density of

the dispersion medium

g

= Acceleration due to gravity

ηo = Viscosity of the medium

Note: The

question holds spheres falling freely without hindrance and at a constant rate.

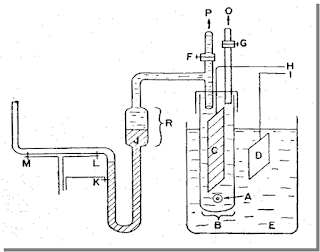

Coulter Counter Method (Electrical

stream sensing zone method)

Coulter

Counter Method (Electrical stream sensing zone method) is a

sophisticated method. It is a precise

and accurate method.

Range of analysis:

Sample preparation and

analysis

conditions

1. Powder samples are dispersed in an

electrolyte to form a very dilute suspension

2. The suspension is usually subjected to ultrasoni agitation for a period to break up any particle agglomerates.

3. A dispersant may also be added to aid particl deagglomeration.

2. The suspension is usually subjected to ultrasoni agitation for a period to break up any particle agglomerates.

3. A dispersant may also be added to aid particl deagglomeration.

Principle

of Measurement

1.The particle suspension is drawn through an aperture

accurately drilled through a sapphire crystal set into the wall of a hollow

glass tube.

2. Electrodes, situated on either side of the aperture and

surrounded by an electrolyte solution.

3. Monitor the change in electrical signal which occurs

when a particle momentarily occupies the orifice and displaces its own volume

of electrolyte..

4. The volume of suspension drawn through the orifice is

determined by the suction potential created by a mercury thread rebalancing in

a convoluted U tube.

5.The volume of electrolyte fluid which is displaced in the

orifice by the presence of a particle causes a change in electrical resistance

between the electrodes which is proportional to the volume of the

particle.

6.The

change in resistance is converted between into a voltage pulse which is

amplified and processed electronically .

7.

Pulses falling within pre-calibrated limits or thresholds are used to split the particle size distribution

into many different size ranges.

In

order to carry out size analysis over a wide diameter range it will

be necessary to change orifice diameter

used, to prevent

Coarse

particles blocking a small diameter orifice . Conversely, finer particles in a

large diameter orifice will cause too small a relative in volume to be accurately

quantified.

Advantages : 1. It is one of the

precise and accurate method.

2. Analysis range is wide.

Disadvantages: 1. It is a sophisticated

method.

2. It is a expensive

method.

Posting Komentar